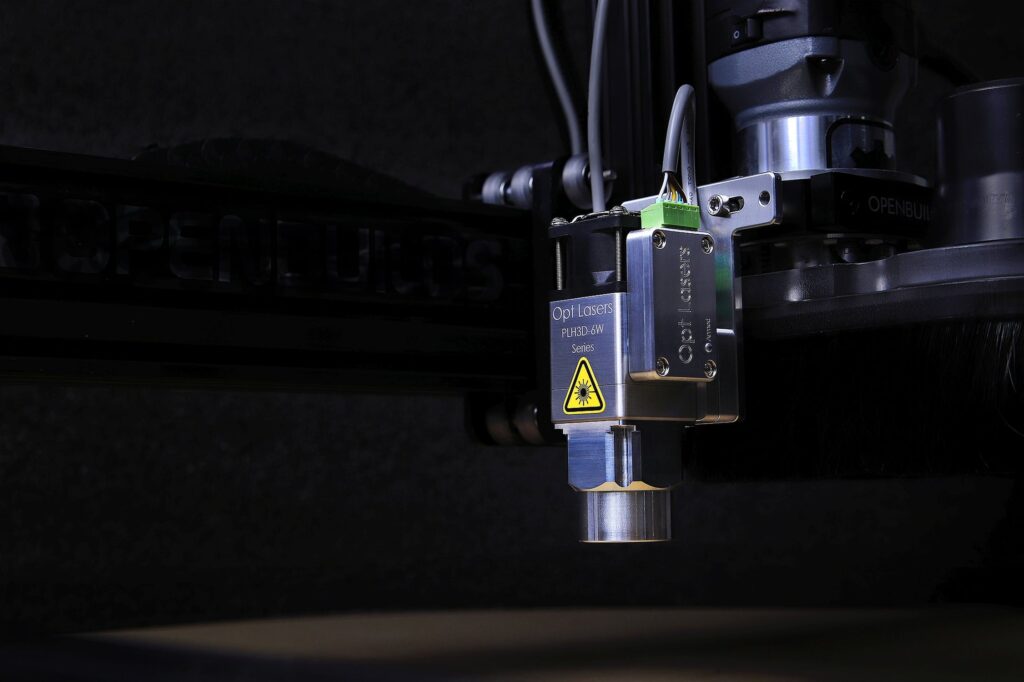

Computer Numerical Control (CNC) Machining is a strategy used to play out a wide scope of assembling or manufacturing assignments completely done by automated gadgets. Now because of digitization, they are highly used. They help the specific company to do the manufacturing tasks easily.

CNC machining produces precise and explicit parts with every creation. They are responsible for producing specific parts and things. The programming of CNC machines and programming guarantees consistency in every one of the pieces. Devices utilized in remote detecting depend on a similar innovation, each opportunity to come by exact outcomes. If you are thinking of buying a new CNC milling machine, it is important for you to know about some of the tips and mistakes you might make. Further, we will discuss all of them in detail.

Some Of The Tips And Mistakes To Avoid When Buying Your First Cnc Milling Machines:

Many potential CNC machine buyers did not know some important things to know before buying the CNC machine. This is why it is important for you to scroll down and read the tips that you must keep in mind while purchasing the machine for the first time.

1. Know the Full Cost:

When you first buy something you don’t have enough idea about the cost. Any machinery you purchase is not always going to be cheap. You must know it’s sadly a certainty that a CNC machine won’t be cheap. They are not so expensive that you can’t afford them are certain brands and companies that may offer you a CNC machine at a medium rate, i.e. not so costly and not so cheap.

Even though it is not usually so cheap, it assures you durability and quality. It will ensure you get the most potential value for your money. As you are searching for your first CNC machine, you’re probably going to be searching for an utilized CNC machine, which saves you a huge load of cash. However, any enormous piece of gear is continuously going to be all speculation, so it means a lot to pick a reasonable model.

If you believe in one big investment and lifetime relief, then it is a recommendation to go for a new CNC milling machine. Any machine, utilized or new, will work in the long run, through no shortcoming issue of your own, and you presumably must fix it.

2. Buying From The Appropriate Manufacturer:

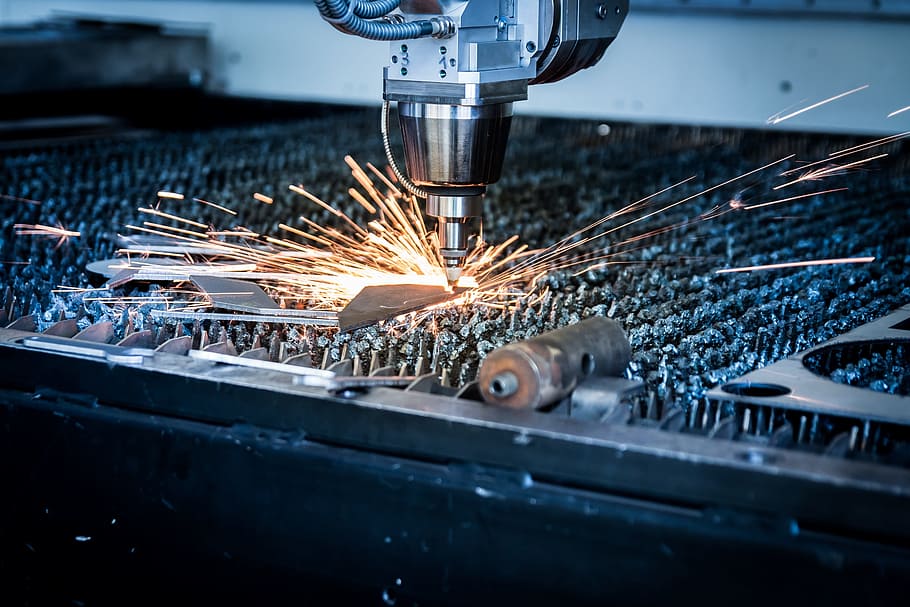

If you plan to buy a new CNC milling machine for yourself, it is important for you to buy from an appropriate and reliable manufacturer so that the quality and durability cannot be compromised. Many CNC machine manufacturers ask for a lot of money but, in return, do not give justice to the quality they provide. This is why it is highly important to invest your money in a certain brand of Machines that ensures you provide a good computer numerical milling machine.

Many new buyers make the mistake of buying a machine from any manufacturer, and in the future, they have to face the consequences. Some of the consequences include frequently stopping the engine, the products are not made on time, and many other things. You must buy the machine from the best CNC machine shop so that the machine will work up to its potential.

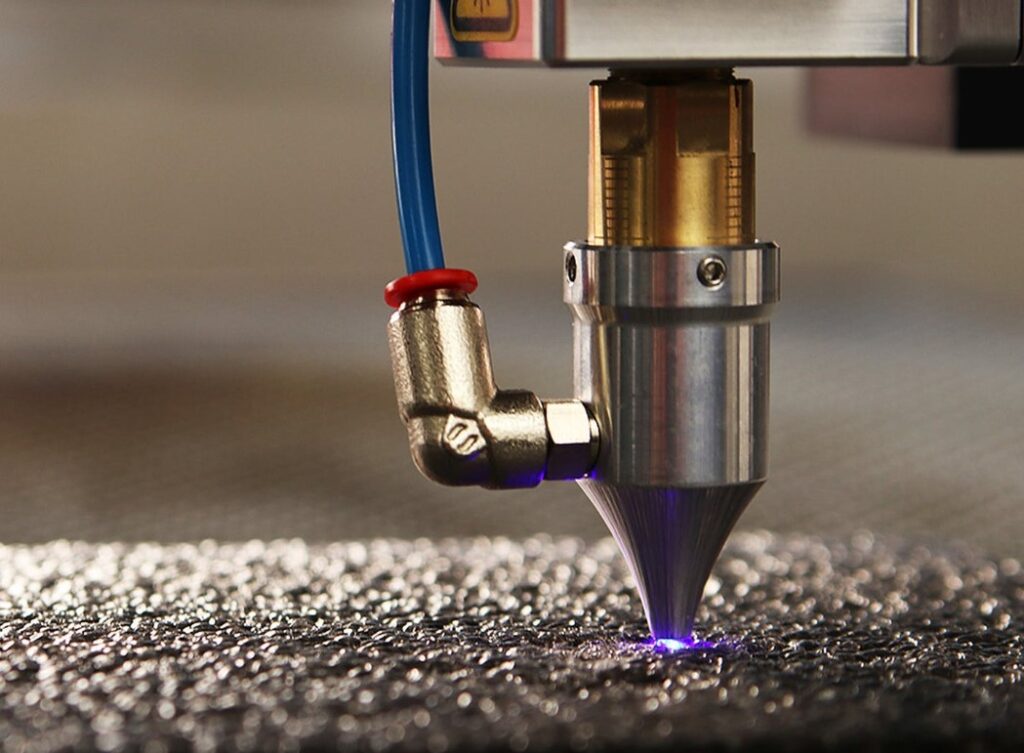

3. Know The Project For Which You Need The Machinery:

Chances are, you’re prepared to consider putting resources into a CNC machine that could cost you a large number of dollars; you have basically a harsh thought of what you need to make with it. All things considered, ensuring you completely grasp what kind of parts you’re attempting to assemble is vital. What items are going to be produced through this machine is important for you to know. You’re searching for the right machine for your requirements; you must learn what metals can be processed through the machine. Size is additionally significant: how enormous of a working environment will you want? All these points matter a lot.

Many buyers do not have comprehensive knowledge about the production process and whether the product they are aiming for will be made through the machine. So first, know your plan and procedure, then invest your money. How much accuracy will you really want to make the parts you need to? What about speed? Is it vital to you that you’re ready to finish occupations rapidly? First, you must be sure about this.

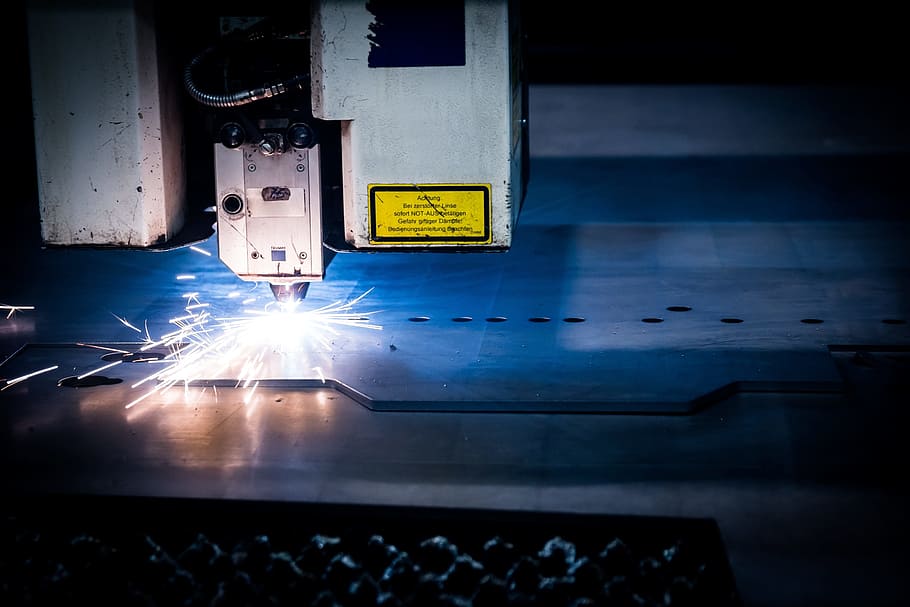

4. Ensure You Can Program Your Machine:

Maybe the most widely recognized problem, particularly among experienced mechanics doing the change to CNC, is purchasing a machine they are unfamiliar with. They don’t have enough idea about how it will work and still buy a new CNC milling machine. People make this mistake, and as a solution, here is a tip that you can follow, which is always doing good research. Check out some experts and learn more about the specifications and features of the CNC milling machine so that you can be pretty sure about the decision to buy it for yourself.

Undoubtedly, not all CNC machines are made equivalent, and each brings its own difficulties and benefits with regard to coding. Assuming you’re new to working CNC machines at all, you’d most likely be most attractive for a model that involves conversational programming as, while a cycle restricting, it’s a decent spot to begin and doesn’t need a very remarkable coding foundation.

In the event that you’ve worked with CNC machines previously, however, you must be familiar with the computer coding and many other things so that it won’t be an issue for you, but if you want to know more about its features and new working techniques, then you also need to do some research first.

Parting Words:

Generally, people make all these mistakes, and if you are planning to buy one for your company or factory, it is advised to first check out all these tips so that you don’t make these mistakes.