It’s easy to think that the world of mechanics, metalwork and materials is of the past, and today’s engineering and technology landscape is one of software, algorithms and advanced materials.

But behind every sleek smartphone, every electric vehicle and every advanced manufacturing robot lies an entire universe of mechanical precision. But what exactly powers the machines that power our world? The answer starts deeper than most people realise. It’s in the tools that shape, cut and define the materials we depend on every day.

The Invisible Foundations

When we talk about innovation, the conversation often heads toward more ephemeral but contemporary things like artificial intelligence or cloud computing. These are undoubtedly transformative technologies, but they all rely on physical components: Circuit boards, metal housings, precision gears and structured frames. Creating those components is a feat of high-level engineering. Every precisely milled surface or intricately cut groove begins with a tool designed to cut through some of the toughest materials on Earth.

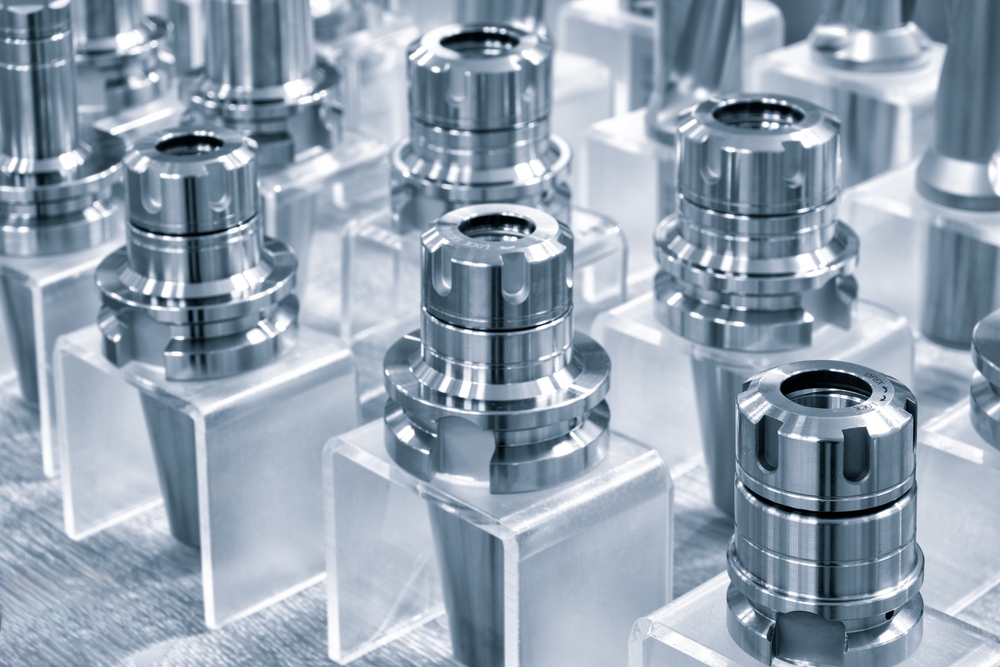

One of the most important (yet largely unsung) contributors in this realm is the world of industrial cutting tools. These tools are what allow raw metals to become precision parts. They’re not glamorous, but without them, the gadgets we love and the vehicles we rely on wouldn’t exist.

Why Materials Matter

At the heart of advanced machining lies the tool material itself. Just as you wouldn’t build a skyscraper with cheap cement, manufacturers don’t shape high-grade metals with just any cutting tool. Here’s where carbide comes in – an exceptionally hard material that can endure high temperatures and maintain a razor-sharp edge under extreme pressure.

Solid carbide endmills are crafted entirely from this high-performance material. Unlike traditional high-speed steel tools, which may wear down quickly or lose their edge during intensive processes, solid carbide tools remain sharp and effective over extended periods, especially at high cutting speeds. This makes them invaluable in industries where precision and durability are essential, such as aerospace, automotive and medical device manufacturing.

The Tools Behind the Transformation

Even as digital innovation redefines manufacturing, physical tools remain a constant. CNC (Computer Numerical Control) machines have revolutionized the way products are made, but their performance still depends heavily on the cutting tools they use. If a CNC machine is the brain and muscle, then the endmill is the hand, carrying out the command with accuracy and force.

Solid carbide endmills come in various shapes and configurations to meet the needs of specific jobs. Whether it’s roughing out a block of hardened steel, threading a large bore or creating fine contours in aluminium, these tools allow manufacturers to cut not only metal but also things like production time, error rates and long-term costs. In competitive industries, these are essential metrics.

A Small Tool with a Global Impact

It’s easy to overlook the small things when thinking about global industry. But it’s often the smallest components that make the biggest difference. The ability to shape hard metals with consistency and precision enables every modern convenience we take for granted. The car you drive, the phone in your hand and the buildings you walk past every day all depend on reliable, high-quality machining.

Tools like carbide endmills may not make many headlines and may never have done so. But they remain a critical part of the story. One of the critical steps in the birth of the modern industrial age was the development of machines and tools that could reproduce their own precision and quality – machines that could make other machines.

The acquisition and production of machine tools like endmills are still a crucial step as developing nations seek to build modern economies. And as industries continue to evolve and materials become more advanced, the tools used to work them must keep pace.