Manufacturing operations have come a long way with the integration of automated systems that streamline processes, increase efficiency, and improve overall productivity. From robotics and artificial intelligence to IoT devices and advanced analytics, these technological advancements have revolutionized the way factories operate.

In this article, we will explore some of the top automated systems that are making waves in the manufacturing industry, offering innovative solutions to enhance operations and drive success in this competitive market. With a focus on efficiency, quality, and cost-effectiveness, these systems are paving the way for the factories of the future.

Introduction to Automated Systems in Manufacturing

Automated systems in manufacturing have revolutionized the industry, streamlining processes, increasing efficiency, and improving overall productivity. These systems leverage cutting-edge technology to automate repetitive tasks, perform quality control inspections, and optimize production schedules.

Automated systems in manufacturing have revolutionized the industry, streamlining processes, increasing efficiency, and improving overall productivity. These systems leverage cutting-edge technology to automate repetitive tasks, perform quality control inspections, and optimize production schedules.

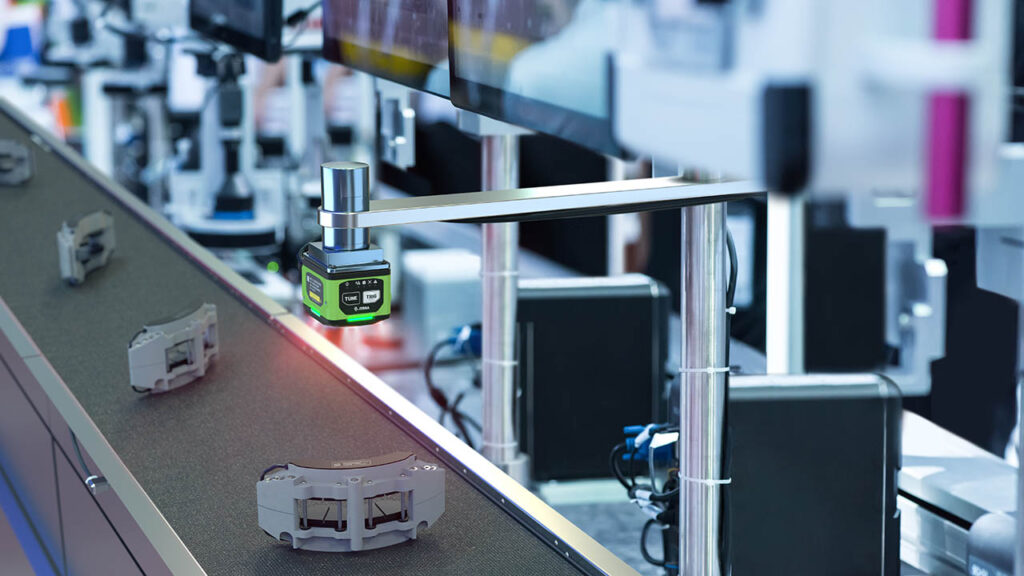

From robotic arms that assemble products with precision to AI-powered machines that detect defects in real-time, automated systems are reshaping the manufacturing landscape. By integrating these advanced technologies into their operations, manufacturers can enhance their competitive edge and meet the demands of todays fast-paced market.

Benefits of Implementing Automation in Manufacturing Operations

There are numerous benefits to be gained from implementing automation in manufacturing operations. One of the key advantages is increased efficiency and productivity.

There are numerous benefits to be gained from implementing automation in manufacturing operations. One of the key advantages is increased efficiency and productivity.

Automated systems can perform tasks quickly and accurately, thereby reducing the time it takes to complete various processes. This results in higher output levels and improved overall performance.

Additionally, automation can lead to cost savings by reducing the need for manual labor and minimizing errors in production. By streamlining operations and increasing consistency, companies can also enhance product quality and customer satisfaction. Overall, automation in manufacturing can help businesses stay competitive in todays rapidly evolving market.

Top Automated Systems for Improving Manufacturing Efficiency

The top automated systems for improving manufacturing efficiency encompass a wide range of innovative technologies that are revolutionizing the industry.

From robotic automation and artificial intelligence to IoT connectivity and predictive analytics, these advanced systems are streamlining production processes, optimizing resource allocation, and enhancing overall productivity. By leveraging these automated solutions, manufacturers can reduce downtime, minimize errors, and improve quality control across the board.

With features such as real-time data monitoring, intelligent machine learning algorithms, and autonomous decision-making capabilities, these cutting-edge systems are reshaping the future of manufacturing operations. By investing in these automated technologies, companies can stay ahead of the competition and drive sustainable growth in the rapidly evolving market landscape.

Conclusion

In conclusion, the use of top automated systems in manufacturing operations has revolutionized the industry by increasing efficiency, reducing costs, and improving overall productivity. These systems, such as robotics, AI, and IoT devices, have enabled manufacturers to streamline processes, minimize errors, and stay competitive in todays fast-paced market.

By implementing manufacturing management software alongside these automated systems, companies can further optimize their operations and achieve greater success in the industry. It is clear that automation is the way forward for manufacturing, and companies that embrace these technologies will undoubtedly see significant benefits in the long run.