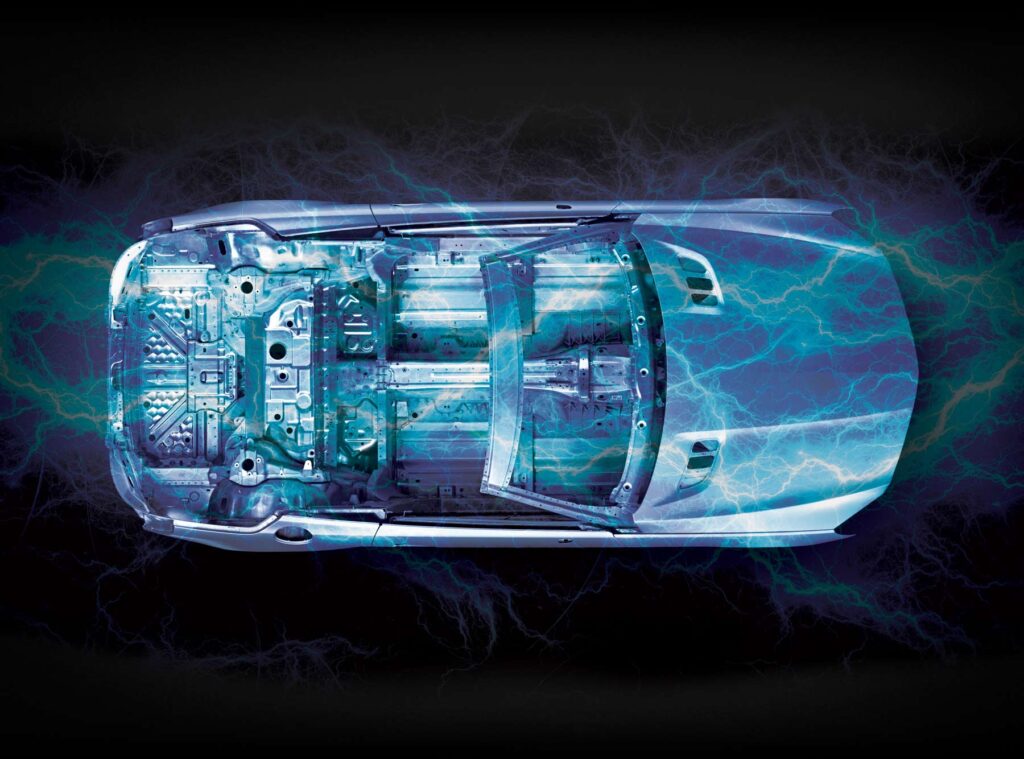

The automotive industry is on the cusp of a revolution. With new advancements in technology, manufacturers are now able to create lighter and more fuel-efficient cars by utilizing aluminum extrusions.

This method of lightweight has the potential to significantly enhance the performance of vehicles while reducing their environmental footprint. In this article, we will explore how aluminum extrusion can be used to improve automotive performance and why it may become an integral part of future car designs.

Introduction to Automotive Lightweighting with Aluminum Extrusions

Aluminum extrusions are rapidly becoming an essential component of the automotive industry to achieve maximum performance. This article will provide an introduction to the concept of lightweight with aluminum extrusions and explore how it can be used to enhance vehicle performance.

We will look at some of the potential benefits that aluminum offers, such as improved fuel economy, greater strength and durability, and better corrosion resistance. Additionally, will discuss the various types of extruded shapes available for use on vehicles and how they can be tailored for specific applications.

Finally, this article will provide a comprehensive overview of why lightweight aluminum extrusions are quickly becoming a standard for automotive manufacturers around the world.

Benefits of Using Aluminum Extrusions for Enhancing Automotive Performance

Aluminum extrusions offer a variety of benefits that can help enhance automotive performance. For starters, aluminum is an incredibly lightweight material, making it ideal for vehicles where every ounce counts.

Aluminum has excellent strength-to-weight ratio and corrosion resistance which makes it the perfect choice when designing components to withstand extreme temperatures or conditions. It also offers superior heat dissipation capabilities, allowing components to stay cooler longer even under high loads and speeds.

Additionally, aluminum extrusions are extremely easy to manufacture with precision shapes and sizes so they can be used in a wide range of applications from structural supports to powertrain systems. Finally, due to its lightweight nature, aluminum can reduce fuel consumption as well as carbon emissions which helps make automobiles greener overall.

As such, using aluminum extrusions for automotive performance enhancement is becoming increasingly popular among manufacturers who are looking for ways to improve their vehicle’s efficiency without sacrificing safety or quality standards.

Challenges and Solutions in Implementing Aluminum Extrusions for Automotive Applications

Lightweighting has become an increasingly popular solution for improving automotive performance, and the use of aluminum extrusions offers a unique approach to achieving this. While aluminum extrusions can provide multiple benefits, they also come with certain challenges that must be addressed to implement them effectively.

These challenges range from the limited availability of suitable alloys to cost considerations and quality control issues. In addition, there are design constraints associated with using aluminum extrusions due to their lightweight nature and flexibility.

To address these challenges and successfully implement aluminum extrusion solutions for automotive applications, manufacturers must take into account the specific properties of the alloy being used as well as its cost implications. Quality control procedures should also be established to ensure that each component meets stringent specifications throughout its lifecycle. Designers should consider how best to integrate these components into existing vehicle architectures while taking advantage of their superior strength-to-weight ratio capabilities when it comes time for production processes such as welding or painting operations.

Finally, manufacturers need to ensure they have adequate resources available in terms of personnel and equipment at every step along the value chain from raw material procurement through the final assembly stages to deliver top-quality results on time while controlling costs at every stage.

Conclusion

The future of automotive performance is looking brighter with the use of vehicle aluminum extrusions, as they offer lightweight solutions that enhance vehicle performance while reducing fuel consumption and emissions. Aluminum extrusions are a cost-effective way to reduce overall weight and improve efficiency in vehicles, making them an ideal choice for automakers looking to improve their fleet’s performance.

As technology advances and production costs decrease, more manufacturers will likely begin utilizing aluminum extrusion technology in their cars. With this shift towards lighter vehicles, consumers can expect improved efficiency, fuel economy, and environmental benefits from the use of aluminum extrusions in automotive applications.