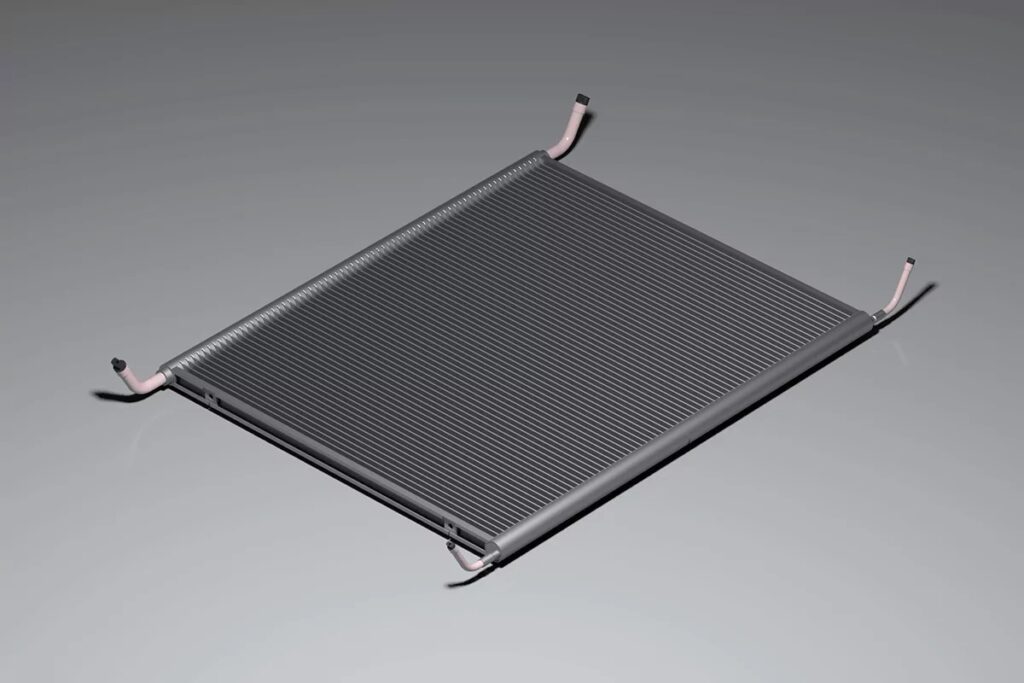

Microchannel coils are rapidly gaining traction in various industries due to their efficient design and enhanced thermal performance. These compact heat exchangers consist of numerous small channels that allow for increased heat transfer rates while minimizing the overall size and weight of the equipment. Such advantages are crucial in applications where space and efficiency are paramount.

Increased Efficiency in HVAC Systems

In heating, ventilation, and air conditioning (HVAC) applications, the demand for energy-efficient solutions is ever-growing. Microchannel coils have emerged as a solution to this challenge, delivering superior heat exchange capabilities. The larger surface area relative to volume results in improved thermal performance, enabling systems to operate with lower refrigerant charges compared to traditional coils.

Furthermore, themicro channel coil technology facilitates the use of environmentally friendly refrigerants, aligning with global sustainability goals on Kaltra. This compatibility and enhanced performance make microchannel coils an ideal choice for modern HVAC systems.

Automotive Industry Applications

The automotive sector has witnessed significant advancements through the integration of microchannel technology. These coils are employed in automotive radiators and condensers to effectively manage engine temperature and optimize cabin comfort. Their lightweight construction contributes to overall vehicle efficiency, positively impacting fuel consumption and emissions.

Research indicates that vehicles equipped with microchannel heat exchangers can achieve up to 30% reductions in weight compared to conventional counterparts. This reduction is crucial in the race to build lighter and more efficient vehicles, making microchannel coils a pivotal innovation in automotive design.

Refrigeration and Cooling Solutions

Microchannel coils are also prevalent in commercial refrigeration units. The compact size and high efficiency of these coils are essential for applications such as supermarket refrigeration, where space is limited, and energy costs are significant. The design allows for greater surface area in a smaller footprint, enhancing the cooling capacity without requiring larger units.

In addition, microchannel technology’s ability to operate effectively at varying pressures and temperatures makes it suitable for diverse cooling applications, from food preservation to industrial cooling processes.

Challenges and Considerations

Despite the numerous advantages, there are challenges associated with implementing microchannel coils. One primary concern is the potential for clogging due to the small channel sizes, particularly in environments with dirty or contaminated fluids. Regular maintenance and monitoring are essential to ensure optimal performance.

Moreover, the manufacturing process of microchannel coils can be complex, involving precise engineering and material selection to withstand thermal and mechanical stresses. It necessitates collaboration between designers, engineers, and manufacturers to achieve the desired results.

Future Trends and Innovations

As industries continue to evolve, the applications of microchannel coils are expected to expand. Innovations in materials, such as the use of advanced alloys and coatings, will enhance durability and performance under various operating conditions. Additionally, the integration of smart technologies may lead to the development of self-monitoring systems that can predict maintenance needs, further enhancing efficiency.

In summary, microchannel coils represent a significant advancement in heat exchange technology, with applications spanning HVAC, automotive, and refrigeration industries. The ongoing research and innovations in this field promise to unlock new potentials and efficiencies that can benefit numerous sectors. The future of thermal management is indeed bright with the continuing evolution of microchannel technology.